The modular LED strip holders and a box for them were the results of a couple hours at Techshop this evening.

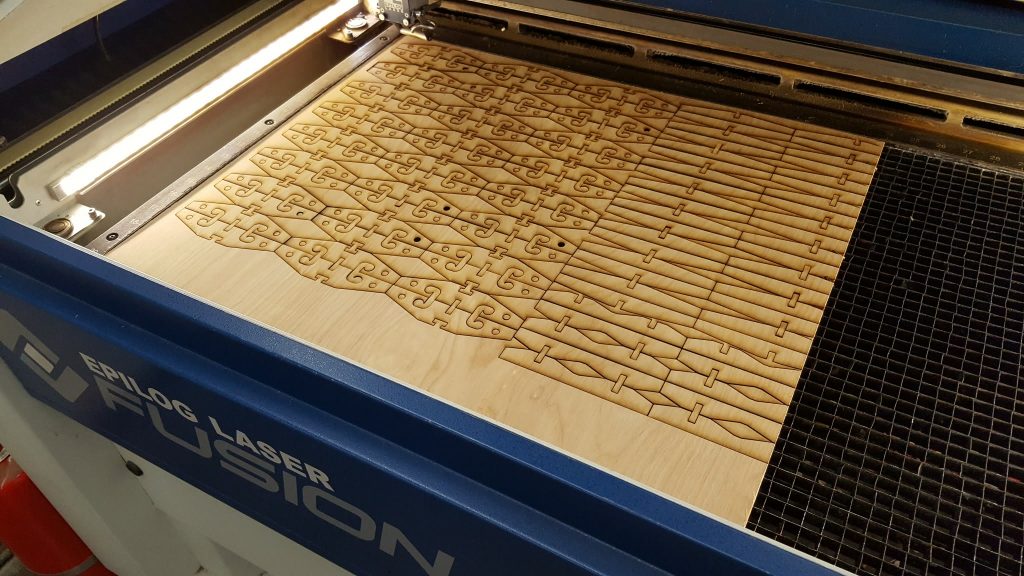

Modular Cable Management

Laser cutting the holders took about 27 minutes for the 88+ pieces. Then it took another 8 minutes because my wood was 24″ wide rather than the 26″ that I designed the cut pattern for and I had to recut the last column. Whoops. I brought extra stock with me for these types of things.

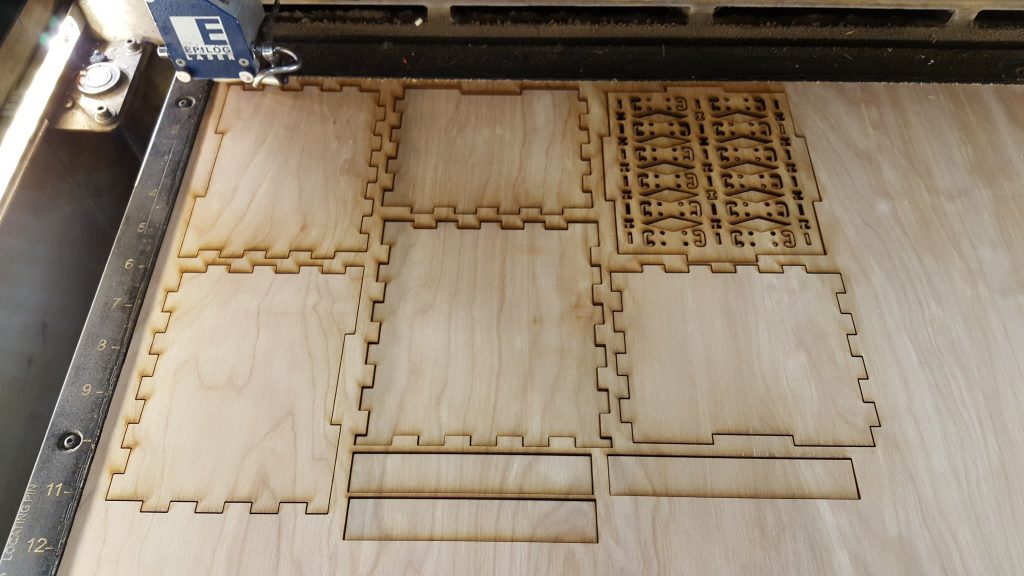

Cable Management Module Management

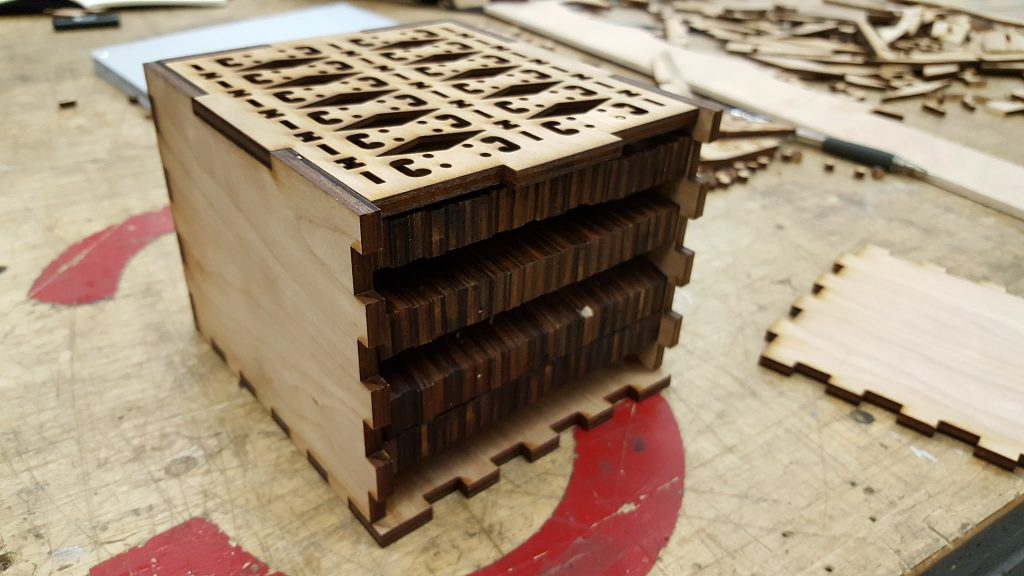

With all those pieces I needed a box to hold them in when they aren’t installed.

The box I designed holds 88 pieces in as dense a form as I could figure out. There are 44 of the pieces that the cables and LEDs sit in, 36 cross bar legs and eight double cross bar legs. That’s enough for a piece every meter, and two at every 5 meter joining of strips.

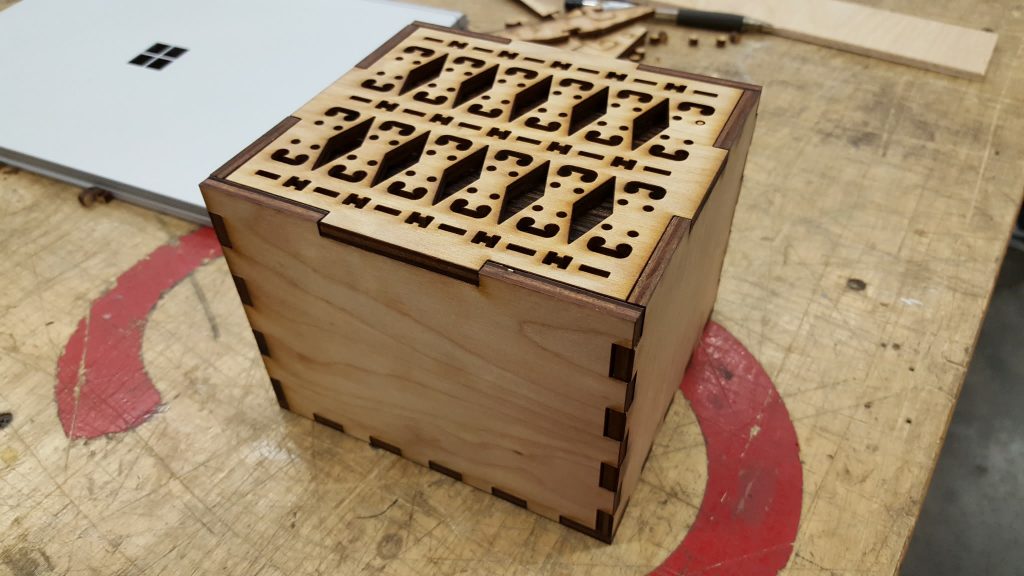

The box took about 7 minutes to cut. It snapped together perfectly the first time. I’m pretty proud of that one since I designed all the interlocking fingers as I was drawing it in Illustrator.

The pattern on the top of the box is taken from the cutting pattern of the modular arms, so it subtly hints at what’s inside.